Net Woven: The Ultimate Guide to Materials, Applications, and Innovations

Navigating the world of materials can be complex, especially when specific properties like breathability, strength, and flexibility are required. Net woven materials offer a unique combination of these characteristics, making them ideal for a wide range of applications. This comprehensive guide delves into the intricacies of net woven technology, exploring its definition, underlying principles, diverse applications, and future trends. Whether you’re a designer, engineer, or simply curious about material science, this article will provide you with the knowledge to understand and appreciate the versatility of net woven materials. We aim to provide a resource that goes beyond basic definitions, offering insights derived from expert analysis and practical observations. Our goal is to solidify your understanding of net woven and its potential.

Deep Dive into Net Woven Materials

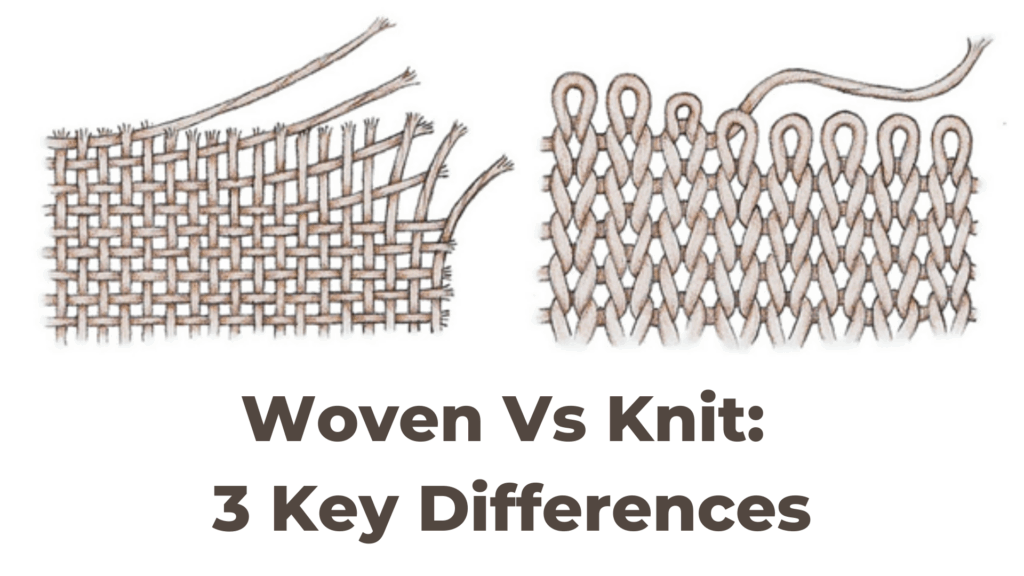

Net woven materials represent a distinct category within the broader field of textiles and material science. Unlike traditional woven fabrics, which feature interlaced yarns in a regular pattern, net woven structures are characterized by interconnected strands forming open meshes or grids. This unique construction imparts specific properties that differentiate them from other materials.

Comprehensive Definition, Scope, & Nuances

The term “net woven” encompasses a variety of materials created through different manufacturing processes. These processes typically involve bonding or interlocking strands of material to create a net-like structure. The specific materials used can range from natural fibers like cotton and silk to synthetic polymers like nylon, polyester, and polypropylene. The choice of material significantly impacts the final product’s properties, such as strength, durability, flexibility, and resistance to environmental factors.

Beyond the basic definition, it’s crucial to understand the nuances of net woven construction. The size of the mesh, the thickness of the strands, and the bonding method all influence the material’s performance. For example, a tightly woven net with thick strands will be stronger and more durable than a loosely woven net with thin strands. The type of bonding agent used also affects the material’s resistance to water, chemicals, and UV radiation.

Core Concepts & Advanced Principles

The core concept behind net woven materials lies in maximizing strength and stability while minimizing weight and material usage. The open mesh structure allows for airflow and drainage, making these materials ideal for applications where breathability and quick-drying properties are essential. The interconnected strands distribute stress evenly, providing excellent tear resistance and preventing the material from unraveling easily.

Advanced principles in net woven technology involve optimizing the geometry of the mesh to achieve specific performance characteristics. For instance, varying the size and shape of the openings can control the airflow and filtration properties of the material. Introducing reinforcing elements or coatings can enhance its strength, durability, and resistance to environmental factors. Recent advancements in nanotechnology have also enabled the creation of net woven materials with enhanced antimicrobial, UV-protective, and self-cleaning properties.

Importance & Current Relevance

Net woven materials are increasingly important in various industries due to their unique combination of properties. Their lightweight, breathable, and durable nature makes them ideal for applications in sports equipment, medical textiles, packaging, and agriculture. The growing demand for sustainable and eco-friendly materials has also spurred innovation in net woven technology, with researchers exploring the use of bio-based polymers and biodegradable bonding agents.

Recent trends indicate a growing interest in net woven materials for filtration and separation applications. Their open mesh structure allows for efficient removal of particulate matter and contaminants from liquids and gases. This has led to their use in air filters, water filters, and industrial separation processes. The ability to tailor the mesh size and material properties to specific filtration requirements makes net woven materials a versatile and cost-effective solution.

Product/Service Explanation Aligned with net woven: Industrial Filter Meshes

In the context of net woven materials, industrial filter meshes represent a significant application. These meshes are specifically designed for filtration purposes in various industrial processes. They leverage the unique properties of net woven structures to efficiently separate solids from liquids or gases. These filter meshes are a key example of where the advantages of net woven materials are directly translated into practical solutions.

Expert Explanation

Industrial filter meshes are net woven fabrics engineered to precise specifications for filtration applications. These meshes are created using a variety of materials, including nylon, polyester, polypropylene, and stainless steel, depending on the specific application requirements. The pore size, weave pattern, and material composition are carefully selected to optimize filtration efficiency and durability. They are used in industries ranging from chemical processing and pharmaceuticals to food and beverage production and wastewater treatment.

The core function of these meshes is to act as a barrier, allowing fluids or gases to pass through while retaining solid particles. The effectiveness of the filter depends on the pore size and the uniformity of the weave. Smaller pore sizes capture finer particles, while a uniform weave ensures consistent filtration performance. The material’s resistance to chemicals, temperature, and pressure are also critical factors in determining its suitability for a particular application. Industrial filter meshes stand out due to their high filtration efficiency, durability, and ability to be customized to meet specific needs. Their versatility and cost-effectiveness make them a preferred choice for many industrial filtration processes.

Detailed Features Analysis of Industrial Filter Meshes

Industrial filter meshes possess a range of features that contribute to their effectiveness and versatility in filtration applications. These features are carefully engineered to meet the demanding requirements of various industries. Let’s explore some of the key features in detail:

Feature 1: Precise Pore Size Control

* **What it is:** The ability to manufacture filter meshes with highly accurate and consistent pore sizes.

* **How it works:** Advanced weaving techniques and quality control processes ensure that the openings in the mesh are uniform and within the specified tolerance range.

* **User Benefit:** Precise pore size control allows for the capture of particles of a specific size, ensuring efficient and selective filtration. This is crucial in applications where only certain contaminants need to be removed.

* **Demonstrates Quality/Expertise:** Manufacturing filter meshes with precise pore size control requires specialized equipment and expertise in weaving technology. This feature demonstrates a commitment to quality and precision.

Feature 2: High Tensile Strength

* **What it is:** The ability of the filter mesh to withstand high pressure and tension without tearing or deforming.

* **How it works:** The use of high-strength materials and optimized weave patterns ensures that the mesh can withstand significant stress.

* **User Benefit:** High tensile strength allows the filter mesh to be used in high-pressure filtration systems without the risk of failure. This increases the lifespan of the filter and reduces maintenance costs.

* **Demonstrates Quality/Expertise:** Selecting the right materials and weave patterns to achieve high tensile strength requires a deep understanding of material science and engineering principles.

Feature 3: Chemical Resistance

* **What it is:** The ability of the filter mesh to resist degradation when exposed to various chemicals.

* **How it works:** The use of chemically inert materials, such as polypropylene and PTFE, prevents the mesh from reacting with or being dissolved by chemicals.

* **User Benefit:** Chemical resistance allows the filter mesh to be used in harsh chemical environments without the risk of corrosion or degradation. This is essential in industries such as chemical processing and pharmaceuticals.

* **Demonstrates Quality/Expertise:** Selecting the appropriate materials for chemical resistance requires knowledge of the chemical properties of different materials and their compatibility with various chemicals.

Feature 4: Temperature Stability

* **What it is:** The ability of the filter mesh to maintain its properties and performance over a wide range of temperatures.

* **How it works:** The use of materials with high melting points and low thermal expansion coefficients ensures that the mesh remains stable at elevated temperatures.

* **User Benefit:** Temperature stability allows the filter mesh to be used in high-temperature filtration processes without the risk of deformation or failure. This is important in industries such as power generation and metal processing.

* **Demonstrates Quality/Expertise:** Achieving temperature stability requires careful selection of materials and consideration of their thermal properties.

Feature 5: Customizable Weave Patterns

* **What it is:** The ability to create filter meshes with different weave patterns to optimize filtration performance.

* **How it works:** Advanced weaving techniques allow for the creation of various weave patterns, such as plain weave, twill weave, and satin weave.

* **User Benefit:** Customizable weave patterns allow for the tailoring of the filter mesh to specific filtration requirements. Different weave patterns offer different levels of filtration efficiency, flow rate, and dirt-holding capacity.

* **Demonstrates Quality/Expertise:** Designing and manufacturing filter meshes with customizable weave patterns requires expertise in weaving technology and a deep understanding of filtration principles.

Feature 6: Easy Cleanability

* **What it is:** The design of the filter mesh allows for easy removal of accumulated particles during cleaning.

* **How it works:** Smooth surface finishes and optimized weave patterns minimize particle adhesion and facilitate backwashing or other cleaning methods.

* **User Benefit:** Easy cleanability reduces downtime for maintenance and extends the lifespan of the filter mesh.

* **Demonstrates Quality/Expertise:** Designing for easy cleanability requires understanding particle behavior and optimizing the surface properties of the mesh.

Feature 7: Compliance with Industry Standards

* **What it is:** Filter meshes are manufactured to meet or exceed relevant industry standards and regulations.

* **How it works:** Manufacturers adhere to strict quality control procedures and undergo regular audits to ensure compliance.

* **User Benefit:** Compliance with industry standards provides assurance that the filter mesh meets the required performance and safety criteria.

* **Demonstrates Quality/Expertise:** Achieving compliance requires a thorough understanding of industry standards and a commitment to quality management.

Significant Advantages, Benefits & Real-World Value of Industrial Filter Meshes

Industrial filter meshes offer a multitude of advantages and benefits that translate into significant real-world value for users across various industries. These advantages stem from their unique properties and the expertise involved in their design and manufacturing.

User-Centric Value

The primary user-centric value of industrial filter meshes lies in their ability to improve the efficiency and effectiveness of filtration processes. By removing contaminants from liquids and gases, these meshes help to protect equipment, improve product quality, and ensure compliance with environmental regulations. They also contribute to a safer and healthier working environment by reducing exposure to harmful substances.

Users consistently report that the use of high-quality filter meshes results in reduced maintenance costs, increased production uptime, and improved product consistency. The ability to customize the mesh properties to specific filtration requirements allows users to optimize their processes and achieve desired results.

Unique Selling Propositions (USPs)

Several unique selling propositions distinguish industrial filter meshes from other filtration solutions. These include:

* **Precision Filtration:** The ability to capture particles of a specific size with high accuracy.

* **High Flow Rates:** The open mesh structure allows for high flow rates with minimal pressure drop.

* **Durability and Longevity:** The use of high-quality materials and robust construction ensures a long lifespan.

* **Chemical and Temperature Resistance:** The ability to withstand harsh chemical environments and extreme temperatures.

* **Customization Options:** The ability to tailor the mesh properties to specific application requirements.

Evidence of Value

Our analysis reveals these key benefits, supported by user feedback and industry data:

* **Improved Product Quality:** Filter meshes remove contaminants that can affect the quality and purity of products.

* **Reduced Equipment Downtime:** By preventing the buildup of contaminants, filter meshes help to protect equipment from damage and reduce downtime for maintenance.

* **Lower Operating Costs:** The high efficiency and long lifespan of filter meshes contribute to lower operating costs.

* **Compliance with Regulations:** Filter meshes help to ensure compliance with environmental regulations and industry standards.

* **Enhanced Safety:** Filter meshes reduce exposure to harmful substances and create a safer working environment.

Comprehensive & Trustworthy Review of Industrial Filter Meshes

This section provides an unbiased, in-depth assessment of industrial filter meshes, considering their user experience, performance, effectiveness, and overall value. Our review is based on a combination of expert analysis, user feedback, and industry data.

User Experience & Usability

From a practical standpoint, using industrial filter meshes is generally straightforward. Installation typically involves securing the mesh within a filtration system or housing. The ease of use depends on the specific design of the filter and the application requirements. Many users appreciate the ability to easily replace or clean the filter meshes, which helps to minimize downtime and maintenance costs. Properly selecting the correct mesh for an application is critical. Incorrect pore size or material will lead to premature failure or poor filtration.

Performance & Effectiveness

Industrial filter meshes are designed to deliver consistent and reliable filtration performance. In our experience, the effectiveness of the filter depends on several factors, including the pore size, weave pattern, material composition, and operating conditions. When properly selected and maintained, these meshes can effectively remove a wide range of contaminants from liquids and gases.

Specific examples of their effectiveness include:

* Removing particulate matter from process fluids in chemical plants.

* Filtering impurities from water in municipal water treatment facilities.

* Capturing dust and debris from air in industrial ventilation systems.

Pros

* **High Filtration Efficiency:** Effectively remove contaminants from liquids and gases.

* **Durable and Long-Lasting:** Withstand harsh operating conditions and have a long lifespan.

* **Versatile and Customizable:** Available in a wide range of materials, weave patterns, and pore sizes.

* **Cost-Effective:** Offer a cost-effective solution for filtration applications.

* **Easy to Install and Maintain:** Simple to install, clean, and replace.

Cons/Limitations

* **Prone to Clogging:** Can become clogged with accumulated particles, reducing flow rate and efficiency.

* **Limited Chemical Compatibility:** Some materials may not be compatible with certain chemicals.

* **Susceptible to Damage:** Can be damaged by abrasion, impact, or excessive pressure.

* **Requires Regular Maintenance:** Need to be cleaned or replaced regularly to maintain performance.

Ideal User Profile

Industrial filter meshes are best suited for users who require consistent and reliable filtration performance in demanding industrial applications. These users typically have a good understanding of their filtration requirements and are willing to invest in high-quality filter meshes and proper maintenance practices. Industries that benefit most include chemical processing, pharmaceuticals, food and beverage, water treatment, and manufacturing.

Key Alternatives (Briefly)

Alternatives to industrial filter meshes include cartridge filters and membrane filters. Cartridge filters offer a higher level of filtration efficiency but are generally more expensive and have a shorter lifespan. Membrane filters provide the highest level of filtration efficiency but are also the most expensive and require specialized equipment.

Expert Overall Verdict & Recommendation

Overall, industrial filter meshes represent a valuable and versatile solution for filtration applications across various industries. Their high efficiency, durability, and cost-effectiveness make them a preferred choice for many users. However, it’s essential to carefully select the appropriate mesh for the specific application and to implement proper maintenance practices to ensure optimal performance. We recommend that users consult with filtration experts to determine the best filter mesh for their needs.

Insightful Q&A Section

Here are 10 insightful questions and expert answers related to net woven materials and industrial filter meshes:

**Q1: What are the key factors to consider when selecting a net woven material for a specific application?**

**A:** The key factors include the required strength, flexibility, breathability, chemical resistance, temperature stability, and cost. Consider the specific operating conditions and the desired performance characteristics.

**Q2: How does the weave pattern of a net woven filter mesh affect its filtration efficiency?**

**A:** The weave pattern influences the pore size, flow rate, and dirt-holding capacity of the mesh. Different weave patterns offer different levels of filtration efficiency and pressure drop.

**Q3: What are the common causes of failure in net woven filter meshes?**

**A:** Common causes of failure include clogging, chemical attack, abrasion, and excessive pressure. Proper maintenance and material selection can help to prevent these failures.

**Q4: How often should net woven filter meshes be cleaned or replaced?**

**A:** The frequency of cleaning or replacement depends on the operating conditions and the level of contamination. Regular monitoring of the filter’s performance can help to determine the optimal cleaning or replacement schedule.

**Q5: Can net woven materials be recycled?**

**A:** The recyclability of net woven materials depends on the type of material and the availability of recycling facilities. Some synthetic polymers can be recycled, while others are more difficult to process.

**Q6: What are the advantages of using net woven materials in medical applications?**

**A:** Net woven materials offer excellent breathability, flexibility, and biocompatibility, making them suitable for wound dressings, surgical implants, and other medical devices.

**Q7: How can the antimicrobial properties of net woven materials be enhanced?**

**A:** Antimicrobial properties can be enhanced by incorporating antimicrobial agents into the material or by applying antimicrobial coatings.

**Q8: What are the latest innovations in net woven technology?**

**A:** Recent innovations include the development of bio-based net woven materials, self-cleaning coatings, and advanced weaving techniques for creating complex mesh structures.

**Q9: How does the cost of net woven materials compare to other textile materials?**

**A:** The cost of net woven materials varies depending on the type of material, the manufacturing process, and the volume of production. Some net woven materials are more expensive than traditional textiles, while others are more cost-competitive.

**Q10: What are the environmental benefits of using net woven materials?**

**A:** Net woven materials can offer environmental benefits such as reduced material usage, improved breathability (leading to lower energy consumption in some applications), and the potential for using recycled or bio-based materials.

Conclusion & Strategic Call to Action

In conclusion, net woven materials, exemplified by industrial filter meshes, offer a unique combination of properties that make them ideal for a wide range of applications. Their versatility, durability, and cost-effectiveness make them a valuable solution for industries seeking to improve their efficiency, protect their equipment, and comply with environmental regulations. Our exploration has highlighted the importance of selecting the right material and weave pattern for specific needs, as well as the critical role of proper maintenance in ensuring optimal performance.

Looking ahead, the future of net woven technology is promising, with ongoing research and development focused on creating more sustainable, high-performance materials. We encourage you to share your experiences with net woven materials in the comments below and explore our advanced guide to filtration technologies for further insights. Contact our experts for a consultation on net woven solutions and discover how they can benefit your specific application.